Case Study: Steam Hoses

Tire Manufacturer Extends Life of Tire Press Hose Through Flexibility & Fitting Attachment Improvements

A global Tire Manufacturer approached Peerless about a problem they were having with their steam hoses failing prematurely at their Tire Molding & Curing operations. They were currently getting hoses from a Compression Fitting manufacturer and they were having issues with both flexibility and leakage at the fittings. As these hoses are in a very dynamic application, they are constantly being cycled, thereby being impacted by stresses.

Actions

Peerless was provided a sacrificial hose that would be broken down in order to get a better understanding of the design, construction and methodology used for fitting attachment, to see where these stresses were having the greatest impact.

Findings

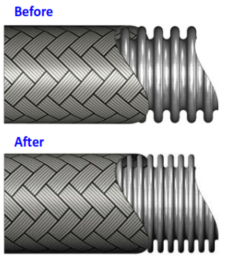

- Flexibility – The flexibility of a metal hose is determined primarily by the number of convolutions per inch; the greater the number, the more flexible it becomes. It was determined that the construction of the hose did not allow for maximum flexibility.

- Leakage – The fittings were leaking where the fittings attachment method was inspected and opportunities for improvement were identified in both the attachment method used as well as the configuration of the hose and fittings.

Recommendations

Peerless suggested a hose with a greater concentration of convolutions. This hose is manufactured in a proprietary manner that results in minimal work hardening, greater consistency in the wall thickness and eliminates residual torsional stress (RTS) during the forming process. These factors enable the hose to have greater deal of flexibility, while providing and a higher cycle life.

Then, based on earlier findings, the Peerless Engineering team made slight changes to the assembly method to ensure a reduction of stresses at any attachment point. Drawings were created and submitted to the customer for review. Two sample hoses were provided for customer to use in a trial.

Outcomes/Testimonial

They have now been slowly replacing their existing hoses to use the Peerless-manufactured solution.

About Peerless

Peerless is a manufacturer of metal hose assemblies and distributor of valves, specialized fittings and instrumentation. Located in Buffalo, NY, USA they have been in business since 1914, under the same family ownership.

If you have any questions, feel free to send us an inquiry online or call us at 1-800-234-3033 and we will get back to you as soon as possible.