Case Studies

Flanged Root Valves: Saving Time & Money with Monoflange Root Valves

A global rotating equipment manufacturer approached Peerless with a request for Root, Drain and Vent valves. After learning there were no concerns with pressure drop in the application, the Slimline Monoflange Valve was suggested.

Tire Press Hoses: Extending Life through Flexibility & Attachment Improvements

A global Tire Manufacturer approached Peerless about a problem they were having with their steam hoses failing prematurely at their Tire Molding & Curing operations.

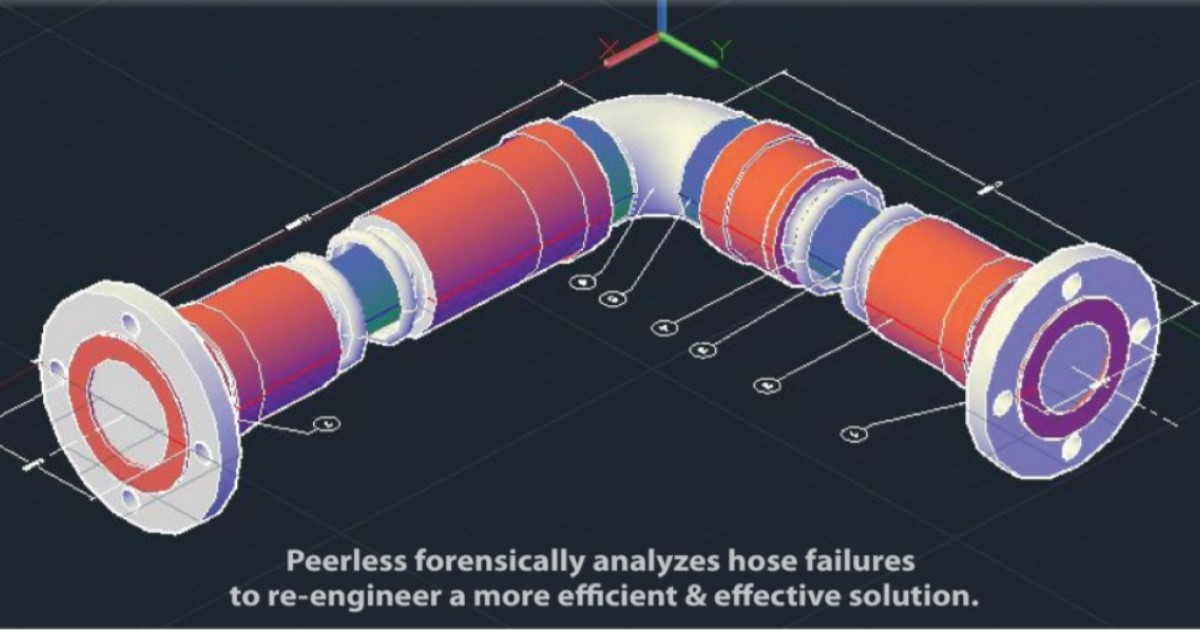

Addressing Failure Modes to Build a Better Hose

A dogleg hose is a hose assembly that has an angled fitting (either a 90° or 45° elbow) installed at some intermediate point between the ends of the hose, specifically not at either end.

FRP CONE for Hatch Sealing and Vapor Recovery

Depending if it's loaded or unloaded, there are potentially strict guidelines that dictate how “tight” a loading operation must be. This is where hatch covers, cones and plugs become necessary.

Peerless Success Stories

-

Medical Tubing, Lumetrics Achieves 75% Labor Savings

A prominent medical tubing manufacturer approached lumetrics with a need for a non-contact, waterless inspection system for their products. OptiGauge provided a system that simultaneously measured tube wall thickness, inner diameter, outer diameter, ovality and concentricity, and automatically downloaded test results to a central data storage system. OptiGauge was installed in a clean room environment, and provided highly accurate measurements in less time, with reduced operator error. OptiGauge can also be installed on their production line providing real-time measurement and feedback to the manufacturing process, without the need for multiple measurement systems and integration required between the different vendors' systems.

-

Trouble Shooting Butterfly Valve Saves Manufacturer Thousands

When one of Peerless' valve clients contacted their representative in the Rochester, NY area with a nagging butterfly valve issue, and our rep & product manager teamed up to provide a lasting solution. After an initial valve survey, our product manager was able to specify a replacement valve that has lasted up to three times longer than the original installation. The savings this solution produced enabled our client to reallocate a sizable percentage of their annual maintenance budget.

-

Batch Control Provides Consistent, Dependable Results

A Midwest meat packaging plant recently introduced a new product, which included one pork rib, 14 ounces of barbeque sauce and a small plastic bag. The challenge was to develop a system in which they could accurately dose the exact volume of sauce from the 55-gallon storage drums. In the beginning the company would place the rib in the bag and then have employees use a small ladle to scoop the sauce from the drum. The company was presented with several accuracy problems with bags containing various amounts of sauce. The inconsistency proved to be costly. The Solution: Standard Pump's Sanitary Batch-Control System (Conductive Solutions). The company mounted the Batch-Control System in 55-gallon drums of sauce and preset the volume for 14 ounces. As the bags passed under the discharge of the system the operator simply pressed the Enter key, which accurately delivered 14-ounce doses.

Why Choose Peerless?

As a leader in industrial process solutions, we uphold the importance of building safe, reliable piping systems engineered to be efficient and sustainable for years to come.

- ISO 9001:2015 Certified

- On-Time Quotes

- Quick Turnaround Times

- On-Time Deliveries

- Application Engineering Support

- Extensive Partnerships

- Advanced ERP & MRP Systems

- 3D CAD/CAM Software

- AML Friendly

- On-Line Chat Support